Hi SZoners,

Yesterday, I went to play on my keyboard, pressed the power button, nothing happened. Pressed harder, nothing again.

For months now the power button along with the other most used ones (intro, var, tempo etc, all of them rubber) were erratic in their behaviour, needed more than a simple tap.

I thought it was age.

This time however, no matter how hard I pressed, nothing happened. So I decided to open the keyboard up, and try to fix it, instead of getting a new one. After all, these are not the best of times to spend 1600€ on a new keyboard. At least that is the price of the S900 here in Greece.

So, this is what I did...

Stage 1:

26 screws, just to remove the upper lid of the keyboard. Here they are, pinned on a sheet of A4 paper, so I can remember which one goes where... take this tip, especially when dealing with screws on plastic.

Stage 2:

26 screws later, upper lid is off. Those foam cable protectors used to be white, then I first opened it up, 10 years ago. Cigarette smoke does that.

My target is in the opposite side of the brown circuit board behind the green circuit board, upper left corner.

Stage 3:

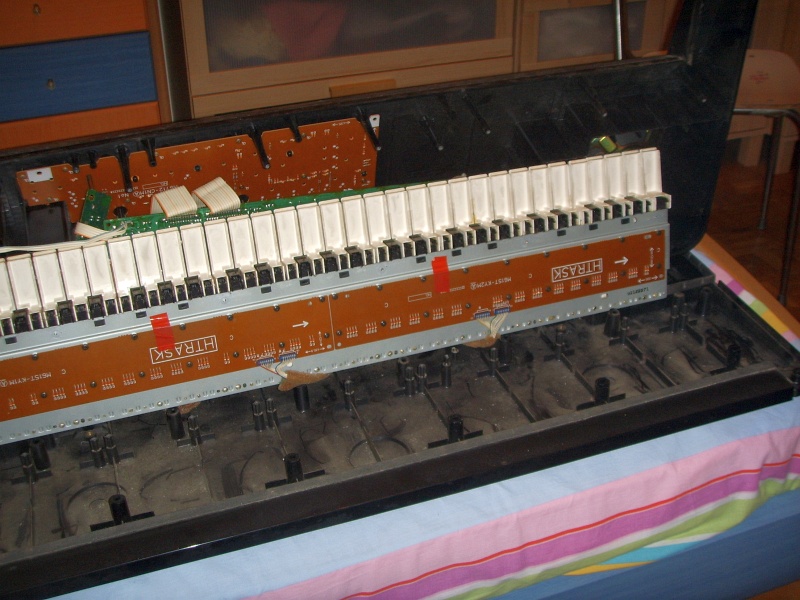

Due to the cable layout and lack of cable length, you have to unscrew the whole keybed, so you have enough space to access the brown PCB.

15 screws later, keybed is off.

Stage 4:

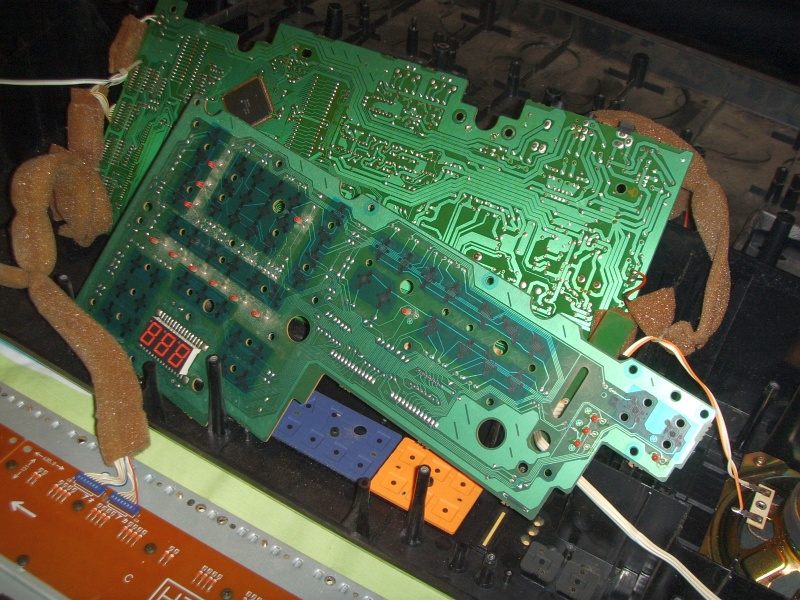

About 8 screws later, green PCB is off, giving access to the brown PCB

Stage 5:

14 screws later, brown pcb is off, showing its green underbelly and various contacts and leds. The one I need to work on is near the lower right corner. It has some kind of muck/dirt in between the contact trails where the button makes contact so, it is rubbing alcohol time, and all the other contacts get a similar treatment as well

Stage 6:

Putting it back together...

63 screws later, the keyboard is ready, the power brick is connected.

Press button, nothing happens ...

press again, nothing happens...

looks like the S900 is going to be my next keyboard after all...

...and then, only then, I realize that the socket for the mains is slightly pulled out!!!Lessons learned: (the fact that I already knew them and used to preach them, makes writing about it much more difficult)

1) Don't attempt to fix things AFTER Sunday roast beef lunch followed by 4 glasses of wine...

2) Always check the cheapest things first. When a printer malfunctions, chances are the $3 cable is at fault, not the $100 printer...

3) For God's sake, check the power cable!

Ahh, by the way... the contacts I cleaned, work like a charm...

A slight touch to the power button, it turns on, a slight caress of the Var2 button, there goes the fill playing...

at least this I got right !!!Theodore

[This message has been edited by trident (edited 03-22-2009).]